Difference between revisions of "Modifying Mail-In Sample Bases"

m |

|||

| (11 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

The standard 11-BM mail-in mounting base accepts a Kapton tube of diameter ~ 0.8 mm and the larger bases accept a tub of diametere ~1.5 mm. The mounted base and [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Supplies_and_Tools#Capillaries:_Kapton matching Kapton tubes] are supplied to users with accepted proposals. | |||

For weak scattering samples (low-Z, such as a typical pharmaceutical powder), users may obtain superior signal-to-noise in their data by using a larger diameter Kapton tube. The larger dimeter results in more diffracting sample material, and thus more counts. Make sure that the larger diameter tube will not result in [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Samples_with_Strong_X-Ray_Absorption high x-ray absorption]. | |||

We suggest using a machine shop lathe or drill to enlarge the inner Kapton tube hole in the mounting base. It is important to ensure that the opening is straight (perpendicular) to the bottom of the base, and centered in the mounting base. The maximum Kapton diameter size (due to the slits on the beamline) is ~ 1.8 mm. | |||

In our experience, the following works well: use a 1/16 inch (0.0625") drill to make the hole larger. Then purchase Cole Parmer brand Kapton tubing (part number # 95820-12) with an outer diameter of 0.0615" (1.56 mm) and inner diameter of 0.0575" (1.46 mm). If done correctly, the Kapton tube should fit snugly into the new larger 1/16" opening. | |||

'''NOTE:''' any larger diameter Kapton tubes must be cut to an maximum length of 7/8" (2.2 cm), and fit inside the plastic magnetic cap. For all capillary tubes, the powder must be correctly positioned for the beam, contained, and secured inside the tube. | |||

Contact 11-BM staff with any questions. | |||

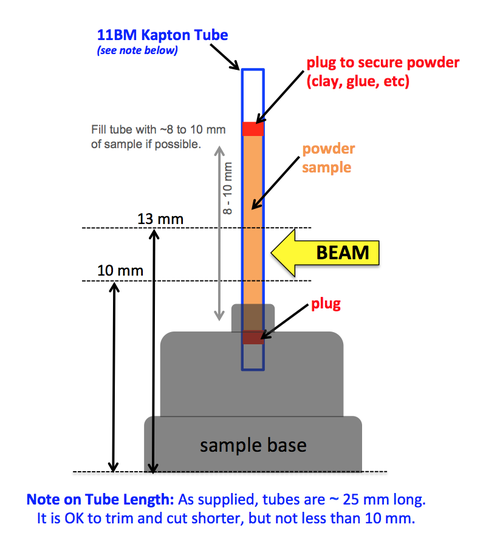

[[image:SampleBase_Diagram.png|500px|Properly prepared sample for the 11-BM mail-in service]] | |||

Latest revision as of 16:22, 19 September 2016

The standard 11-BM mail-in mounting base accepts a Kapton tube of diameter ~ 0.8 mm and the larger bases accept a tub of diametere ~1.5 mm. The mounted base and matching Kapton tubes are supplied to users with accepted proposals.

For weak scattering samples (low-Z, such as a typical pharmaceutical powder), users may obtain superior signal-to-noise in their data by using a larger diameter Kapton tube. The larger dimeter results in more diffracting sample material, and thus more counts. Make sure that the larger diameter tube will not result in high x-ray absorption.

We suggest using a machine shop lathe or drill to enlarge the inner Kapton tube hole in the mounting base. It is important to ensure that the opening is straight (perpendicular) to the bottom of the base, and centered in the mounting base. The maximum Kapton diameter size (due to the slits on the beamline) is ~ 1.8 mm.

In our experience, the following works well: use a 1/16 inch (0.0625") drill to make the hole larger. Then purchase Cole Parmer brand Kapton tubing (part number # 95820-12) with an outer diameter of 0.0615" (1.56 mm) and inner diameter of 0.0575" (1.46 mm). If done correctly, the Kapton tube should fit snugly into the new larger 1/16" opening.

NOTE: any larger diameter Kapton tubes must be cut to an maximum length of 7/8" (2.2 cm), and fit inside the plastic magnetic cap. For all capillary tubes, the powder must be correctly positioned for the beam, contained, and secured inside the tube.

Contact 11-BM staff with any questions.