Difference between revisions of "On-Site Experiments"

| (10 intermediate revisions by the same user not shown) | |||

| Line 18: | Line 18: | ||

* '''Mortar & Pestles''' Small and large agate mortars and pestles are also available for grinding powders. [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Supplies_and_Tools#Mortar_and_Pestle (more details)] | * '''Mortar & Pestles''' Small and large agate mortars and pestles are also available for grinding powders. [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Supplies_and_Tools#Mortar_and_Pestle (more details)] | ||

== | == Beam Profile == | ||

[[Image:diffz.png|frameless| | ===Horizontal - Focused at Sample=== | ||

11-BM beam profile measured at the sample position with tightest horizontal focus possible at the sample position - this focus is commonly used for hot air blower and heating experiments to minimize any temperature differential over a sampled powder volume. | |||

[[Image:diffz.png|frameless|600px| horz profile tightest horizontal focus at the sample position]] | |||

The image below shows a burn of beam shape at the sample position beam with the tightest horizontal focus possible at the sample position. | |||

== more | [[Image:burnfocusatsample.png|frameless|300px| burn tightest horizontal focus at the sample position]] | ||

===Horizontal - Focused at Detector=== | |||

11-BM beam profile measured at the sample position when the beam is '''focused at the detectors''' , this gives the best horizontal detector focus and resolution , but results in a more horizontally broad beam (~ 2 mm) at the sample position. This the default focus for mail-in measurements. A wider beam gives superior powder averaging by sampling a larger volume of powder in the capillary. | |||

[[Image:diffzatdetectors.png|frameless|600px|horz profile with horizontal focus at the detectors]] | |||

The image below shows a burn of beam shape at the sample position beam with the horizontal focus at the detector position and a wider beam at the sample. | |||

[[Image:burnfocusatdetectors.png|frameless|300px| burn horizontal with focus at the detectors]] | |||

===Vertical=== | |||

11-BM beam profile at sample position with standard vertical focus - this is fixed (determined by the 2 mirror in the beamline optics) and does not change with varying horizontal focus. | |||

[[Image:diffy.png|frameless|600px|Vert Beam profile focused.png]] | |||

Latest revision as of 16:59, 1 February 2013

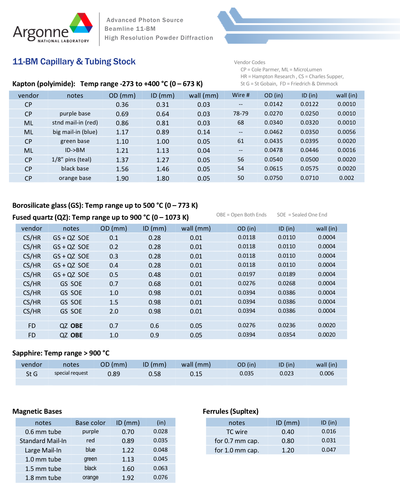

Capillaries

A selection of Kapton, Glass and fused Quartz capillary tubes are available at 11-BM for on-site experiments. Check with staff to confirm, but the materials and dimensions shown in the chart below are typically on hand.

Use quartz for high temperature work ( > 450 C). Glass adds a bit smaller background to the diffraction pattern and is easier to seal, but fused quartz tubes are stronger, more chemical resistant, and survive higher temperatures.

See the Wiki page for more info on capillaries (vendors, sizes etc)

Tools

The following tools might be helpful for preparing samples:

- Small Drill Bits can be useful for loading & packing powder inside Kapton tubes (more details)

- Powder Sieves help remove any large particles and ensure homogeneous powders. 11-BM has a selection of powder sieves available for use by on-site users at the beamline. (more details)

- Mortar & Pestles Small and large agate mortars and pestles are also available for grinding powders. (more details)

Beam Profile

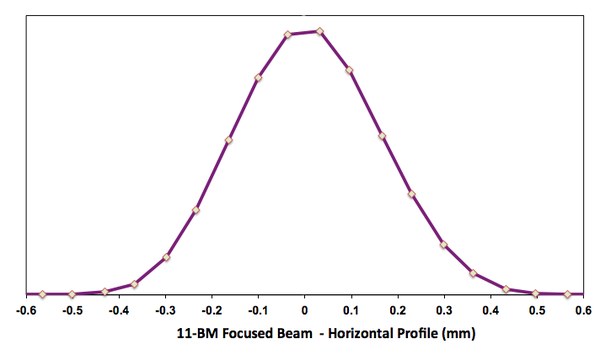

Horizontal - Focused at Sample

11-BM beam profile measured at the sample position with tightest horizontal focus possible at the sample position - this focus is commonly used for hot air blower and heating experiments to minimize any temperature differential over a sampled powder volume.

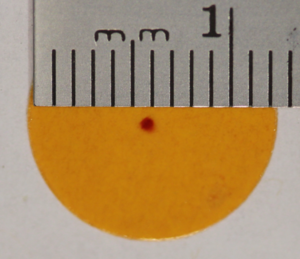

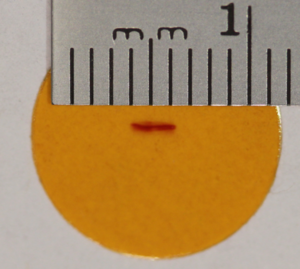

The image below shows a burn of beam shape at the sample position beam with the tightest horizontal focus possible at the sample position.

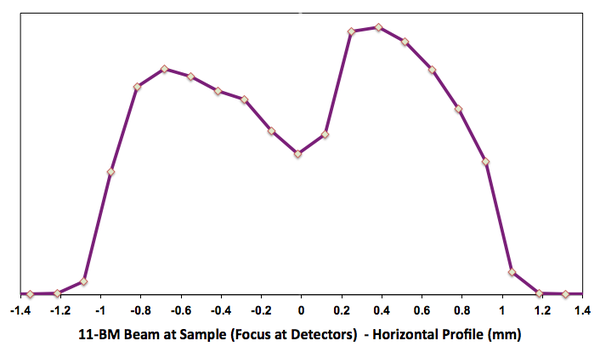

Horizontal - Focused at Detector

11-BM beam profile measured at the sample position when the beam is focused at the detectors , this gives the best horizontal detector focus and resolution , but results in a more horizontally broad beam (~ 2 mm) at the sample position. This the default focus for mail-in measurements. A wider beam gives superior powder averaging by sampling a larger volume of powder in the capillary.

The image below shows a burn of beam shape at the sample position beam with the horizontal focus at the detector position and a wider beam at the sample.

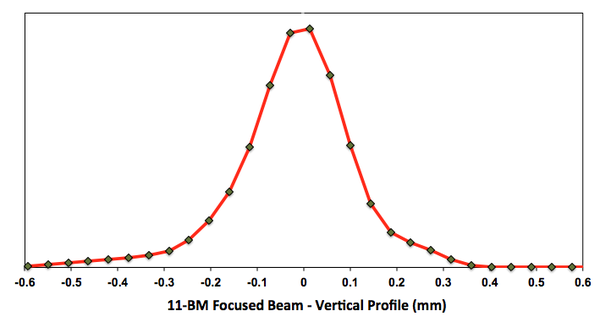

Vertical

11-BM beam profile at sample position with standard vertical focus - this is fixed (determined by the 2 mirror in the beamline optics) and does not change with varying horizontal focus.