Difference between revisions of "Mail-In Powder Diffraction Measurements"

(→Tools) |

|||

| Line 1: | Line 1: | ||

| Line 8: | Line 7: | ||

== Tools == | == Tools == | ||

The following tools might be helpfull for preparing samples: | The following tools might be helpfull for preparing samples: | ||

*Small drill bits [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Equipment_and_Tools#Drill_Bits ( | *Small drill bits can be useful for loading & packing powder inside Kapton tubes [https://wiki-ext.aps.anl.gov/ug11bm/index.php/Equipment_and_Tools#Drill_Bits (more details)] | ||

== Image Gallery== | == Image Gallery== | ||

Revision as of 16:08, 30 May 2012

Tools

The following tools might be helpfull for preparing samples:

- Small drill bits can be useful for loading & packing powder inside Kapton tubes (more details)

Image Gallery

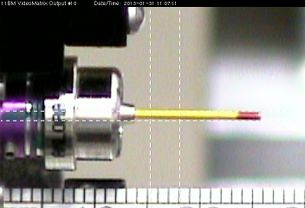

Two views of a sample in position for data-taking, as seen through the "upstream" camera (left) and the video microscope (right). The reticle lines show the nominal extent of the beam. The actual beam edges extend somewhat farther, so these areas should be kept clear of foreign material (glue, clay, wax, etc.). The sample material must be held in place in the beam -- if it is loose in the capillary, it will move when we spin the capillary (we spin at about 5400 r.p.m.). In addition, there must be no lumps of material at the end of the capillary, since this could cause the capillary to bend or break during spinning, and such a lump may also cause a robot malfunction when it attempts to load or unload the sample.