Difference between revisions of "Hot Gas Blower (Cyberstar)"

| (49 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

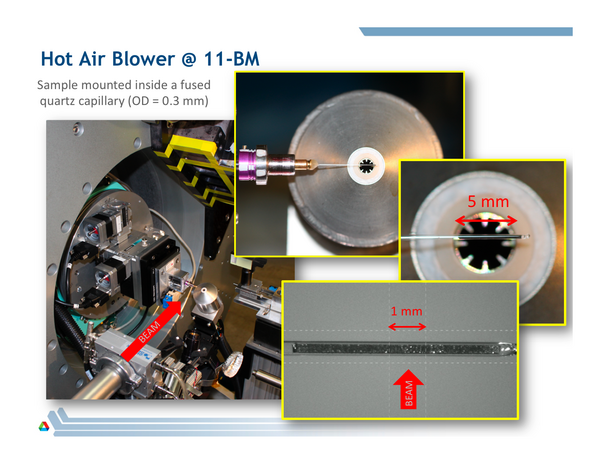

11-BM has a dedicated Cyberstar Hot Gas Blower. This can be used to heat small diameter capillary samples from ambient temperature to ~ 950 °C | 11-BM has a dedicated Cyberstar Hot Gas Blower. This can be used to heat small diameter capillary samples from ambient temperature to ~ 950 °C | ||

== Temperature Range and Ramp Rate == | |||

*Heats small diameter capillary (< 1 mm diameter) samples from ambient temperature (25 °C) up to ~ 950 °C | |||

*Max ramp rate on heating & cooling is 5 deg C/min (300 C/hour). Below 300 °C a faster ramp rate of ~ 10°C/min may be used. | |||

Users should plan experiments to incorporate these limitations on sample size and heating '''and''' cooling ramp times. | |||

== 11-BM Hot Gas Blower | == 11-BM Hot Gas Blower Alignment == | ||

[[Image:HotAirBlowerZoomedImage.png|frameless|600px|Hot Air | [[Image:HotAirBlowerZoomedImage.png|frameless|600px|Hot Air Overview and Alignment ]] | ||

== 11-BM Hot Gas Blower Images == | |||

Mains power (black switch) and Water Flow Interlock Switch are located on the back of the control box. | |||

<gallery mode=packed heights=200px> | |||

Image:WaterFlowPowerSwtich.png |Hot Air Blower Water Lines and Power Switch | |||

Image:HotAirBlower_WaterSupply.png |Hot Air Blower Cooling Water Supply | |||

</gallery> | |||

Turning on the Mains power and cooling water will turn the front LED lights Green and Red, respectively. | |||

Pressing the round GREEN button on the front will turn on the Eurotherm Temperature Controller | |||

<gallery mode=packed heights=200px> | |||

Image:HotAirBlower_MainPower.png | Hot Air Blower Main Power On | |||

Image:HotAirBlower_ControlPower.png | Hot Air Blower Controller Power On | |||

</gallery> | |||

Make sure the the Air flow is turned on (Off/Closed at left, On/Open in the right image) | |||

<gallery mode=packed heights=200px> | |||

Image:HotAirBlower_AirOff.png |Hot Air Blower Air Off | |||

Image:HotAirBlower_AirOn.png |Hot Air Blower Air On | |||

</gallery> | |||

Now the Air flow should be at ~ 500 L/hr, and once aligned to the sample the Hot Gas Blower is ready to use. | |||

<gallery mode=packed heights=200px> | |||

Image:HotGasBlowerAirFlow.png |Hot Air Air Flow | |||

Image:HotAirBlowerReady.png |Hot Air Ready to Use | |||

</gallery> | |||

== Turning the Hot Gas Blower Off == | |||

When the blower is cool, you may turn off the mains power in the back of the controller. | |||

[[Image:ice.jpeg|frameless|100px|ice.jpeg]] | |||

'''IMPORTANT''': When you are finished with the Hot Gas Blower, or want to switch to the N2 blower, TURN OFF/CLOSE the Air flow for the Hot Gas blower, and cover the mouth with foil or the lid. If left Open/On, the air steam from the Hot Gas blower can interfere with the N2 blower shield gas and result if icing problems when using the N2 blower. | |||

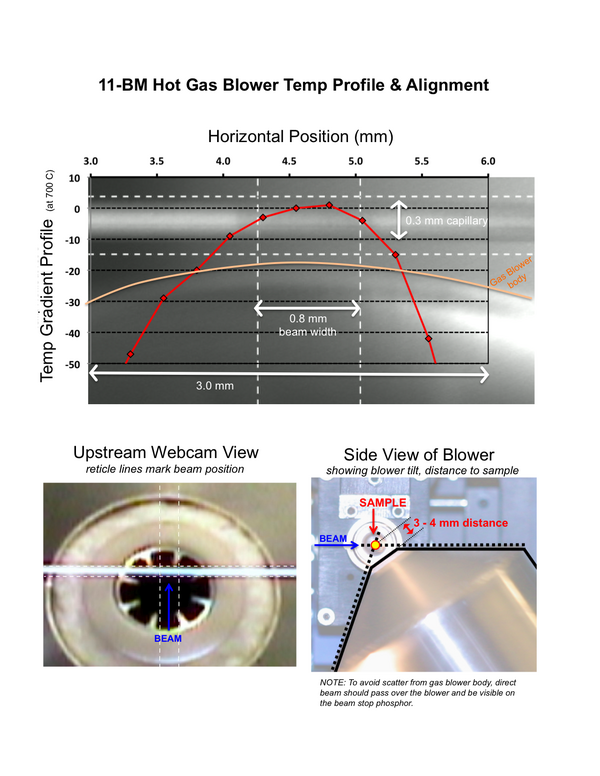

== Temperature Profile & Alignment == | == Temperature Profile & Alignment == | ||

| Line 24: | Line 55: | ||

=== Al2O3 Thermal Expansion === | === Al2O3 Thermal Expansion === | ||

In-situ calibration of the hot gas blower was performed using the known thermal expansion of Al2O3 | In-situ calibration of the hot gas blower was performed using the known thermal expansion of alumina (Al2O3) ''a'' & ''c'' unit cell parameters as a function of temperature. | ||

Full powder diffraction patterns were collected for select "nominal" set temperatures between 100 - 950 C at 11-BM using a 0.5 mm diameter fused quartz capillary packed with Al2O3 powder ([https://wiki-ext.aps.anl.gov/ug11bm/index.php/NIST_SRM_Certificates NIST SRM 676a]). | Full powder diffraction patterns were collected for select "nominal" set temperatures between 100 - 950 C at 11-BM using a 0.5 mm diameter fused quartz capillary packed with Al2O3 powder ([https://wiki-ext.aps.anl.gov/ug11bm/index.php/NIST_SRM_Certificates NIST SRM 676a]). | ||

| Line 30: | Line 61: | ||

Refinements were performed against data from each nominal temperature to determine ''a'' & ''c'' unit cell parameters. | Refinements were performed against data from each nominal temperature to determine ''a'' & ''c'' unit cell parameters. | ||

Based on the initial room temperature 25 C lattice values and published thermal expansion equations (<small> | Based on the initial room temperature (25 C) lattice values and published thermal expansion equations (<small>J. Appl. Cryst. (1993). 26, 77-81 </small>), "real" observed sample temperatures were then calculated independently for each set of ''a'' & ''c'' unit cell terms. | ||

Download the Open Office Worksheet here (Internal only): [https://subversion.xray.aps.anl.gov/11BMweb/Internal/trunk/staffdocuments/HighTempCalibration_ThermalExpansion.ods HighTempCalibration_ThermalExpansion.ods] | |||

See also | |||

[http://link.springer.com/chapter/10.1007/10832182_445 Landolt-Börnstein - Group III Condensed Matter Volume 41A1b, 2002, pp 1-17, Group IV Elements, IV-IV and III-V Compounds. Part b - Electronic, Transport, Optical and Other Properties, Group IV Elements, IV-IV and III-V Compounds. Part b - Electronic, Transport, Optical and Other Properties, Silicon (Si), lattice parameter, thermal expansion] | |||

Approximate room-temperature lattice parameters are: | Approximate room-temperature lattice parameters are: | ||

| Line 36: | Line 73: | ||

''c'' = 12.9934 A | ''c'' = 12.9934 A | ||

The thermal expansion equation used for the ''a'' axis of | The thermal expansion equation used for the ''a'' axis of Al2O3 (range 293-1900 K) is: | ||

delta(a)/a (%) = -0.176 + (5.431E-4 * T) + (2.150-7 * T^2) - (2.810E-11 * T^3) (T/K) | delta(a)/a (%) = -0.176 + (5.431E-4 * T) + (2.150-7 * T^2) - (2.810E-11 * T^3) (T/K) | ||

The thermal expansion equation used for the ''c'' axis of | The thermal expansion equation used for the ''c'' axis of Al2O3 (range 293-1900 K) is: | ||

delta(c)/c (%) = -0.192 + (5.927E-4 * T) + (2.142E-7 * T^2) - (2.207E-11 * T^3) (T/K) | delta(c)/c (%) = -0.192 + (5.927E-4 * T) + (2.142E-7 * T^2) - (2.207E-11 * T^3) (T/K) | ||

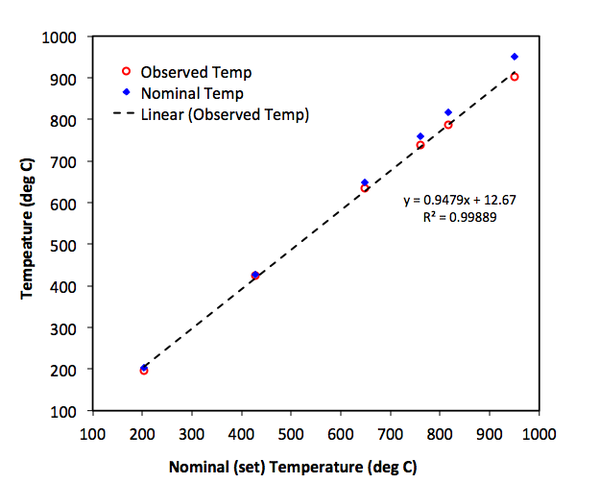

Finally, plotting observed vs nominal set temperatures for the Al2O3 data gives a correction curve and equation for other hot air blower measurements at 11-BM under similar experimental conditions. | Finally, plotting observed vs nominal set temperatures for the Al2O3 data gives a correction curve and equation for other hot air blower measurements at 11-BM under similar experimental conditions. | ||

| Line 50: | Line 86: | ||

T_observed(K) = 0.9479*T_nominal(K) + 12.67 | T_observed(K) = 0.9479*T_nominal(K) + 12.67 | ||

Nominal (Set) Observed Set | Nominal (Set) Observed Obs - Set | ||

deg C deg K deg C deg K deg | deg C deg K deg C deg K deg | ||

25 298 25 295 0 | 25 298 25 295 0 | ||

| Line 81: | Line 117: | ||

==== PbTiO3 ==== | ==== PbTiO3 ==== | ||

[[Image:HotGasBlowerPbTiO3.png|frameless|600px|HotGasBlowerPbTiO3]] | [[Image:HotGasBlowerPbTiO3.png|frameless|600px|HotGasBlowerPbTiO3]] | ||

=== Other Useful High Temperature Transitions === | |||

NOTE: A guide only! '''Caveat Emptor''' Check any and all of these values before using ! | |||

''taken from "Industrial Applications of X-Ray Diffraction, Frank Smith (Editor), Chapter 39 by Mark Rodriquez'' | |||

{| class="wikitable" | |||

|- | |||

! Material | |||

! Event | |||

! Temp (C) | |||

|- | |||

| KNO3 | |||

| Phase transition Tr - Trig | |||

| 129 | |||

|- | |||

| KNO3 | |||

| Melting | |||

| 334 | |||

|- | |||

| CuCl | |||

| Melting | |||

| 430 | |||

|- | |||

| PbTiO3 | |||

| Phase transition Tet-Cubic | |||

| 490 | |||

|- | |||

| SiO2 (quartz) | |||

| Phase transition alpha beta | |||

| 573 | |||

|- | |||

| KI | |||

| Melting | |||

| 681 | |||

|- | |||

| NaCl | |||

| Melting | |||

| 801 | |||

|- | |||

| Bi2O3 | |||

| Melting | |||

| 820 | |||

|- | |||

| Ag | |||

| Melting | |||

| 962 | |||

|- | |||

| Au | |||

| Melting | |||

| 1064 | |||

|- | |||

| K2SO4 | |||

| Melting | |||

| 1076 | |||

|- | |||

| CaF2 | |||

| Melting | |||

| 1360 | |||

|- | |||

|} | |||

Latest revision as of 20:33, 10 March 2014

About

11-BM has a dedicated Cyberstar Hot Gas Blower. This can be used to heat small diameter capillary samples from ambient temperature to ~ 950 °C

Temperature Range and Ramp Rate

- Heats small diameter capillary (< 1 mm diameter) samples from ambient temperature (25 °C) up to ~ 950 °C

- Max ramp rate on heating & cooling is 5 deg C/min (300 C/hour). Below 300 °C a faster ramp rate of ~ 10°C/min may be used.

Users should plan experiments to incorporate these limitations on sample size and heating and cooling ramp times.

11-BM Hot Gas Blower Alignment

11-BM Hot Gas Blower Images

Mains power (black switch) and Water Flow Interlock Switch are located on the back of the control box.

Turning on the Mains power and cooling water will turn the front LED lights Green and Red, respectively. Pressing the round GREEN button on the front will turn on the Eurotherm Temperature Controller

Make sure the the Air flow is turned on (Off/Closed at left, On/Open in the right image)

Now the Air flow should be at ~ 500 L/hr, and once aligned to the sample the Hot Gas Blower is ready to use.

Turning the Hot Gas Blower Off

When the blower is cool, you may turn off the mains power in the back of the controller.

IMPORTANT: When you are finished with the Hot Gas Blower, or want to switch to the N2 blower, TURN OFF/CLOSE the Air flow for the Hot Gas blower, and cover the mouth with foil or the lid. If left Open/On, the air steam from the Hot Gas blower can interfere with the N2 blower shield gas and result if icing problems when using the N2 blower.

Temperature Profile & Alignment

Temperature Calibration

Al2O3 Thermal Expansion

In-situ calibration of the hot gas blower was performed using the known thermal expansion of alumina (Al2O3) a & c unit cell parameters as a function of temperature.

Full powder diffraction patterns were collected for select "nominal" set temperatures between 100 - 950 C at 11-BM using a 0.5 mm diameter fused quartz capillary packed with Al2O3 powder (NIST SRM 676a).

Refinements were performed against data from each nominal temperature to determine a & c unit cell parameters.

Based on the initial room temperature (25 C) lattice values and published thermal expansion equations (J. Appl. Cryst. (1993). 26, 77-81 ), "real" observed sample temperatures were then calculated independently for each set of a & c unit cell terms.

Download the Open Office Worksheet here (Internal only): HighTempCalibration_ThermalExpansion.ods

Approximate room-temperature lattice parameters are:

a = 4.7592 A c = 12.9934 A

The thermal expansion equation used for the a axis of Al2O3 (range 293-1900 K) is:

delta(a)/a (%) = -0.176 + (5.431E-4 * T) + (2.150-7 * T^2) - (2.810E-11 * T^3) (T/K)

The thermal expansion equation used for the c axis of Al2O3 (range 293-1900 K) is:

delta(c)/c (%) = -0.192 + (5.927E-4 * T) + (2.142E-7 * T^2) - (2.207E-11 * T^3) (T/K)

Finally, plotting observed vs nominal set temperatures for the Al2O3 data gives a correction curve and equation for other hot air blower measurements at 11-BM under similar experimental conditions.

These results (from July 2012) are shown below. These calibration data are kindly shared by Jae-Hyuk Her, GE Global Research.

Corrected temperature values calculated from calibration equation: T_observed(K) = 0.9479*T_nominal(K) + 12.67 Nominal (Set) Observed Obs - Set deg C deg K deg C deg K deg 25 298 25 295 0 100 373 93 366 -7 200 473 188 461 -12 300 573 283 556 -17 400 673 378 651 -22 500 773 472 745 -28 600 873 567 840 -33 700 973 662 935 -38 800 1073 757 1030 -43 900 1173 852 1125 -48 950 1223 899 1172 -51

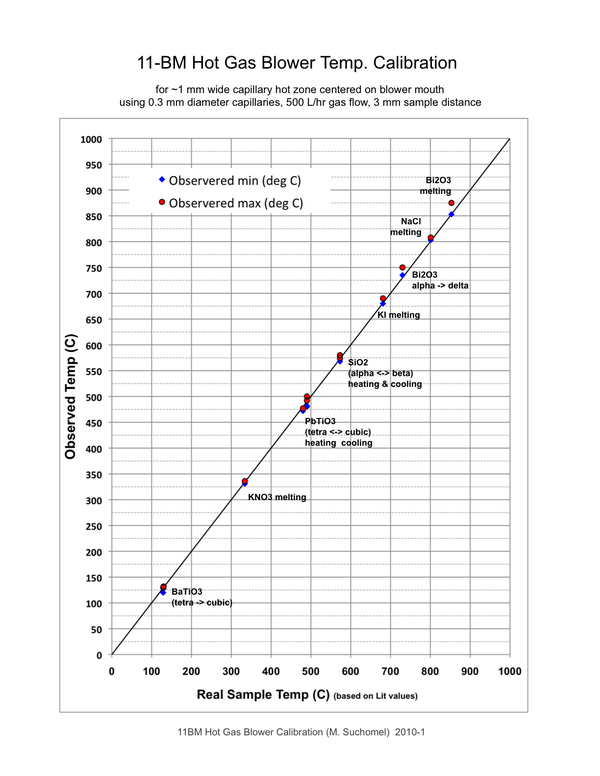

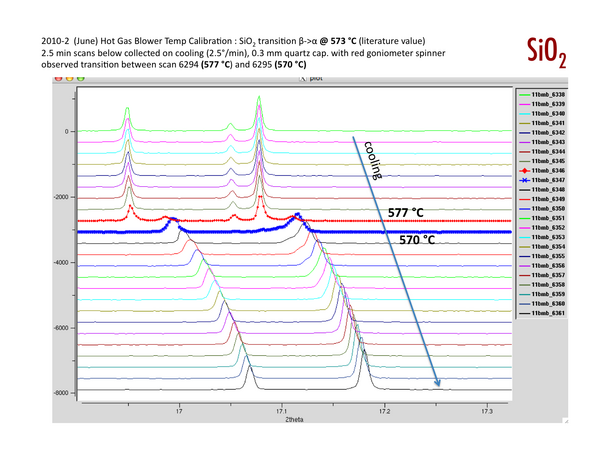

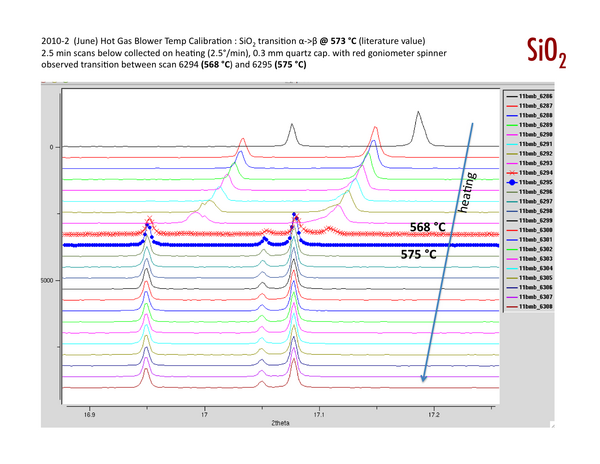

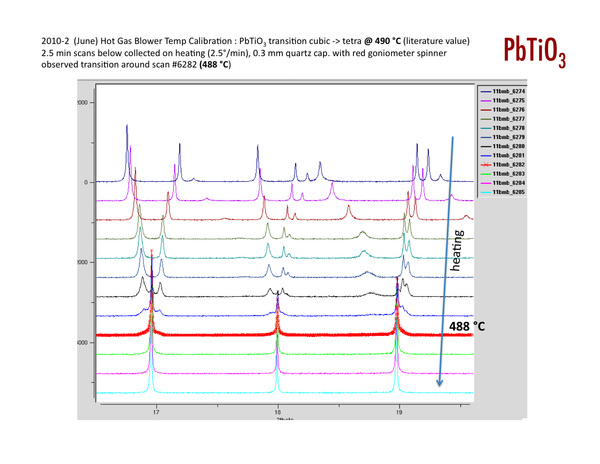

Phase Transitions

The temperature calibration of the hot gas blower was also studied using in-situ diffraction measurements of several known phase transitions. These results (from ~ 2011) are posted below.

SiO2

PbTiO3

Other Useful High Temperature Transitions

NOTE: A guide only! Caveat Emptor Check any and all of these values before using !

taken from "Industrial Applications of X-Ray Diffraction, Frank Smith (Editor), Chapter 39 by Mark Rodriquez

| Material | Event | Temp (C) |

|---|---|---|

| KNO3 | Phase transition Tr - Trig | 129 |

| KNO3 | Melting | 334 |

| CuCl | Melting | 430 |

| PbTiO3 | Phase transition Tet-Cubic | 490 |

| SiO2 (quartz) | Phase transition alpha beta | 573 |

| KI | Melting | 681 |

| NaCl | Melting | 801 |

| Bi2O3 | Melting | 820 |

| Ag | Melting | 962 |

| Au | Melting | 1064 |

| K2SO4 | Melting | 1076 |

| CaF2 | Melting | 1360 |