Difference between revisions of "Hot Gas Blower (Cyberstar)"

| Line 26: | Line 26: | ||

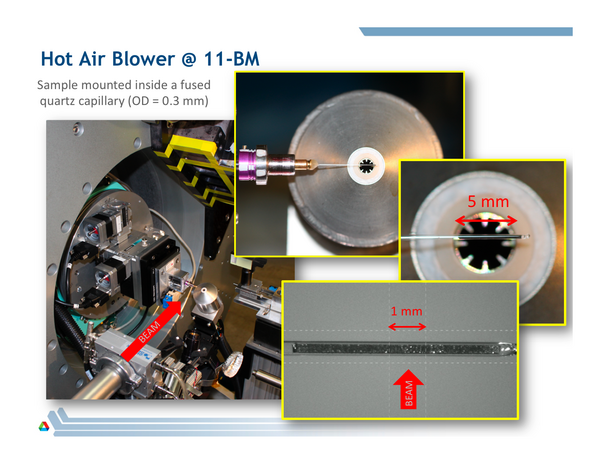

[[Image:HotAirBlower_AirOn.png|frameless|300px|Hot Air Blower Air On]] | [[Image:HotAirBlower_AirOn.png|frameless|300px|Hot Air Blower Air On]] | ||

[[Image:HotAirBlowerReady.png|frameless|400px|Hot Air Ready to Use]] | |||

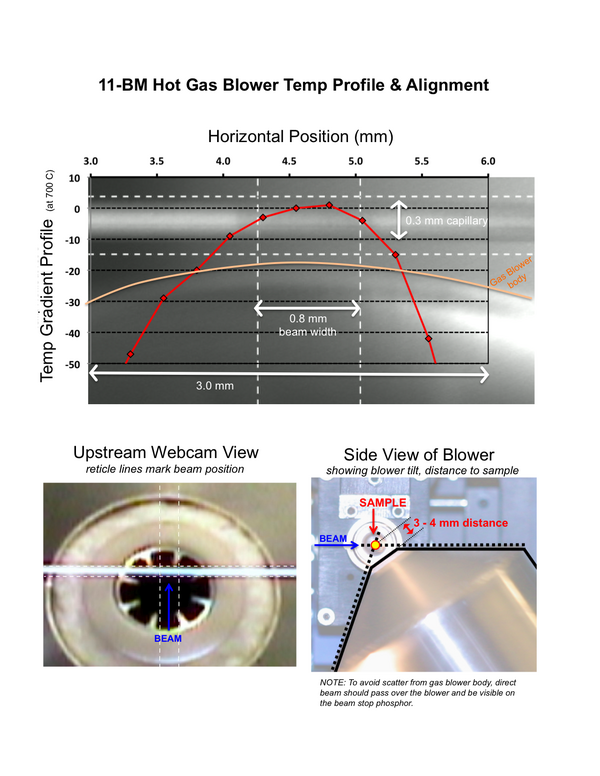

== Temperature Profile & Alignment == | == Temperature Profile & Alignment == | ||

Revision as of 19:48, 20 February 2014

About

11-BM has a dedicated Cyberstar Hot Gas Blower. This can be used to heat small diameter capillary samples from ambient temperature to ~ 950 °C

Temperature Range and Ramp Rate

- Heats small diameter capillary (< 1 mm diameter) samples from ambient temperature (25 °C) up to ~ 950 °C

- Max ramp rate on heating & cooling is 5 deg C/min (300 C/hour). Below 300 °C a faster ramp rate of ~ 10°C/min may be used.

Users should plan experiments to incorporate these limitations on sample size and heating and cooling ramp times.

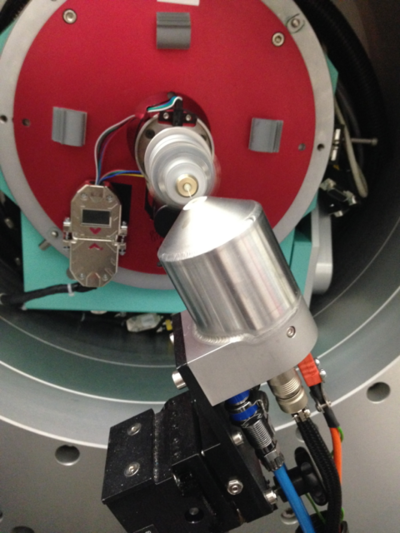

11-BM Hot Gas Blower Images

Temperature Profile & Alignment

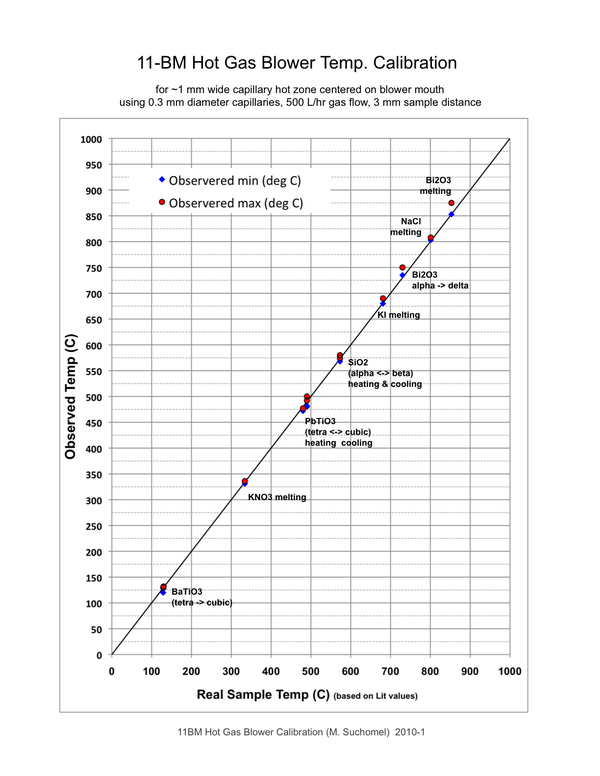

Temperature Calibration

Al2O3 Thermal Expansion

In-situ calibration of the hot gas blower was performed using the known thermal expansion of alumina (Al2O3) a & c unit cell parameters as a function of temperature.

Full powder diffraction patterns were collected for select "nominal" set temperatures between 100 - 950 C at 11-BM using a 0.5 mm diameter fused quartz capillary packed with Al2O3 powder (NIST SRM 676a).

Refinements were performed against data from each nominal temperature to determine a & c unit cell parameters.

Based on the initial room temperature (25 C) lattice values and published thermal expansion equations (J. Appl. Cryst. (1993). 26, 77-81 ), "real" observed sample temperatures were then calculated independently for each set of a & c unit cell terms.

Download the Open Office Worksheet here (Internal only): HighTempCalibration_ThermalExpansion.ods

Approximate room-temperature lattice parameters are:

a = 4.7592 A c = 12.9934 A

The thermal expansion equation used for the a axis of Al2O3 (range 293-1900 K) is:

delta(a)/a (%) = -0.176 + (5.431E-4 * T) + (2.150-7 * T^2) - (2.810E-11 * T^3) (T/K)

The thermal expansion equation used for the c axis of Al2O3 (range 293-1900 K) is:

delta(c)/c (%) = -0.192 + (5.927E-4 * T) + (2.142E-7 * T^2) - (2.207E-11 * T^3) (T/K)

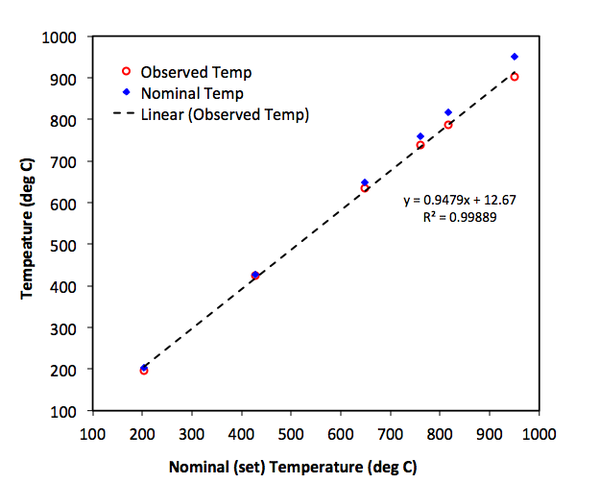

Finally, plotting observed vs nominal set temperatures for the Al2O3 data gives a correction curve and equation for other hot air blower measurements at 11-BM under similar experimental conditions.

These results (from July 2012) are shown below. These calibration data are kindly shared by Jae-Hyuk Her, GE Global Research.

Corrected temperature values calculated from calibration equation: T_observed(K) = 0.9479*T_nominal(K) + 12.67 Nominal (Set) Observed Obs - Set deg C deg K deg C deg K deg 25 298 25 295 0 100 373 93 366 -7 200 473 188 461 -12 300 573 283 556 -17 400 673 378 651 -22 500 773 472 745 -28 600 873 567 840 -33 700 973 662 935 -38 800 1073 757 1030 -43 900 1173 852 1125 -48 950 1223 899 1172 -51

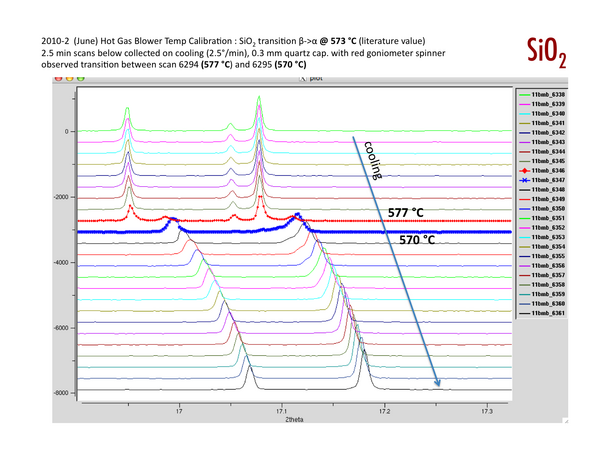

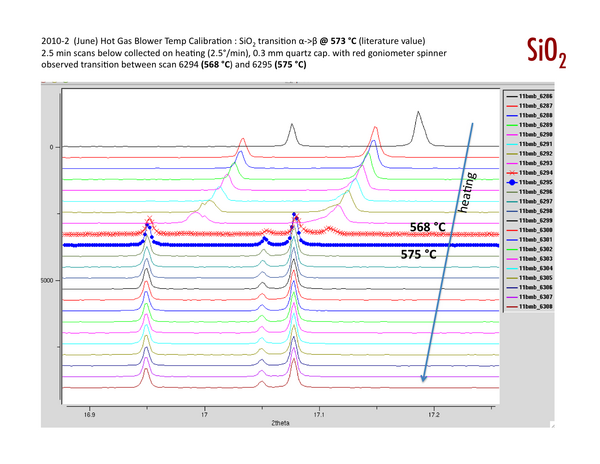

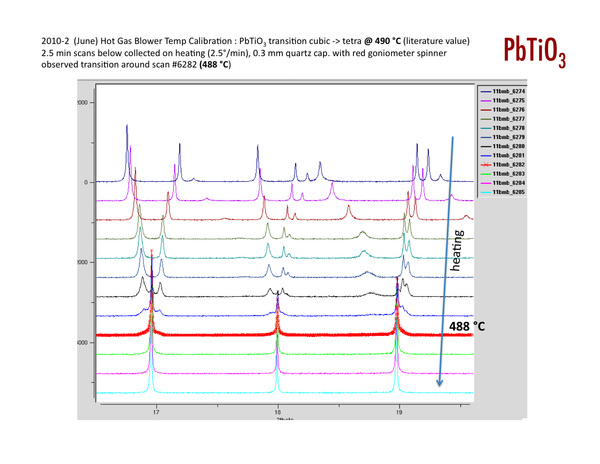

Phase Transitions

The temperature calibration of the hot gas blower was also studied using in-situ diffraction measurements of several known phase transitions. These results (from ~ 2011) are posted below.